Lacking accessibility is like trying to get into your car, only to find someone has parked so close you can’t open the door. It’s a crucial element that often goes unnoticed—until it’s missing. While all designers should prioritize accessibility, it’s especially important for structural designers, who are typically responsible for ensuring people can reach and move through spaces with ease. What may initially seem like a straightforward concept can quickly become complex, as accessibility must be carefully balanced with other design requirements competing for the same space. Whether navigating changes during a project or figuring out how to access a seemingly unreachable area, accessibility must remain a constant priority. In this discussion, we’ll explore standard guidelines for designing with accessibility in mind and delve into some examples where clever design aides in people accessing where they need to be. This will help provide a clearer understanding of how accessibility can be approached—and why it demands careful attention.

Some Considerations when Designing for Accessibility

When beginning the process of designing for accessibility, it’s helpful to start by putting yourself in the user’s position. Imagine, for instance, needing to reach a panel that’s elevated off the ground. Are you designing a solution that allows you to access it easily and safely? Once you’re there, can you move comfortably, or are there obstacles in your way? Is there a risk of bumping your head or other body parts on nearby structures? Can you walk naturally, or are you forced to squeeze through narrow spaces where your clothing might snag due to moving with an awkward gait? Essentially, the goal is to visualize yourself moving through the space smoothly and without unnecessary difficulty. Of course, the complexity of planning for accessibility can vary greatly—from something as simple as providing a step stool to positioning a person high up on a tower, on a suspended platform fastened to a rotating point, while navigating around operating equipment to get to the platform in the first place. Every step along the way demands careful design to ensure a human body can move through the space easily and without incident. To expand your thinking about accessibility, you can also consider asking yourself some of the following questions;

- What needs to be accessed? Depending on the equipment or purposes of the location to reach, the reasons for where you will need to position a person will vary.

- How will it be accessed? Will the person need to walk down a hall or possibly fit through a narrow hole? Will the person need to undergo many elevation changes requiring ladders, or even access somewhere underground?

- How regularly does it need to be accessed? Depending on the frequency of people within the place, you can vary your design. Regular traffic will require more time to design a comfortable solution, where as an area visited only once a year could take a few more liberties, within reason.

- What degree of movement will a person need at this location? Is it a straight path for just walking, or will the location require a person to stretch their arms high up, wide apart, or will they be rotating their body consistently? Places requiring more movement will require more space to allow a person to do this with comfort.

- Is a person expecting to complete a task at the accessed location? This falls in line similarly to ‘degree of movement’, but what someone is doing can heavily impact expected body posture and even introduce elements like required space for regular breaks.

- What will a person be bringing with them to the location? A task usually requires some sort of tools or other equipment to get the job done. Are you providing space for everything brought with them or is there only room for just the person?

As we move though a few example of accessibility, take a moment to ask yourself each of these questions and see how each of them might be applied to each scenario.

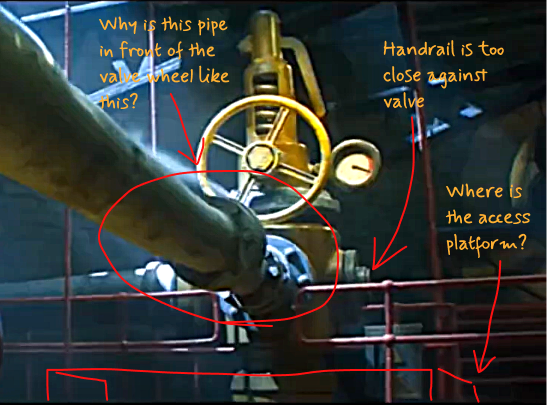

Accessing Industrial Valves

Let’s begin with a basic example of accessibility: ensuring a pipe valve is positioned so it can be easily reached and operated. A common valve type found on industrial sites is the handwheel-operated valve, which controls the flow through the pipe. While the accessibility requirements for this example may seem straightforward, there are a few often-overlooked considerations.

Handwheels are typically around 12 inches in diameter and often require two hands to operate, regardless of whether they’re mounted horizontally or vertically. To turn the wheel, operators usually need to adopt a posture with their elbows extended outward. Ideally, there should be enough clearance around the valve to prevent their arms from bumping into nearby equipment or obstructions.

Another important factor in valve accessibility is its height—specifically, how high the valve is positioned relative to the operator’s standing surface. Valves are typically installed with their center around 3 feet above the standing surface. This height generally allows operators of various sizes to access and operate the valve comfortably, without needing to kneel or bend at the waist. However, it’s just as important to avoid placing valves too high. When a valve is positioned above a comfortable reach, operators are forced to extend their arms upward to turn it—an inefficient and weaker posture, especially when significant force is required.

To ensure comfortable access, there must be sufficient space for an operator to move freely in front of the valve, while also keeping it at a practical height that allows for proper arm positioning and minimizes the need for bending or awkward postures. But what about getting the operator to the valve in the first place?

In some cases, valves are installed near ground level, allowing for straightforward walk-up access. However, it’s equally common for valves to be positioned at elevated heights. In these situations, designers must ensure not only that there is sufficient space around the valve for safe and comfortable operation, but also that there is a practical and efficient means of reaching it.

This might involve incorporating platforms, ladders, stairs, or other access solutions, depending on the specific site conditions. The chosen approach should balance ease of use, practicality, and cost-effectiveness, guiding the operator along a clear and accessible path to the valve.

Wind Turbines

The design and engineering behind a functional wind turbine is nothing short of awe-inspiring. Yet, the constant rotation and wear of the system demand easy access to its internal components. From the outside, these towering structures appear sleek and featureless—tall columns rising to the turbine, with no visible way to ascend (unless you’re a daredevil climber). As you might guess, all accessibility features are cleverly built into the tower’s interior, confined within its 8-meter diameter. Elevating along the height of the column, there are two built methods of accessing its internal components, a ladder and a lift. When designing for the requirements for each of these methods of accessibility, it is a good idea to begin from the base and consider how to get to the next location.

To begin, let’s take a closer look at the internal components of a wind turbine. At the base of the tower, conduit systems, electrical boxes, and cables are neatly arranged and accessible on foot. These cables run vertically along the interior wall, securely fastened as they ascend toward the nacelle—the top housing that contains the generator and rotational components responsible for converting wind into electricity.

Although the cables are enclosed within the tower, they are still subjected to stresses such as thermal fluctuations and vibrational resonance. Over time, these forces can lead to wear and tear, making it essential for maintenance teams to have full access along the tower’s height for inspection and repair.

Two primary access methods are used: ladders and mechanical lifts. Ladders are often installed alongside the cable systems, allowing technicians to stop at any height for close inspection. Their key advantage is that they require no external power—technicians can simply climb to the desired level. However, to comply with building codes and ensure safety, rest platforms must be installed at regular intervals to prevent excessive vertical climbs.

A notable limitation of ladders is that climbers must maintain three points of contact at all times, which restricts their ability to use both hands for repairs. In such cases, a lift may be the preferred option. While it relies on mechanical power to operate, a lift minimizes physical strain and allows maintenance workers to perform tasks more freely with both hands—especially useful for more extensive repairs. Depending on the reason for the visit, one accessibility option can be opted for the other.

Inside the nacelle, critical equipment requires regular maintenance and precise inspection. To support this, workers must be able to move freely and access specific areas with ease. A walkway is constructed around the perimeter of the enclosed equipment, and it must be wide enough to allow for comfortable movement, equipment placement, and close visual or mechanical inspection. This must all be achieved while accounting for the nacelle’s shape and the dimensions of the equipment, ensuring the aerodynamic profile of the nacelle’s housing maintains its slick shape. The nacelle and rotor blades can rotate independently of the tower, allowing them to align with the wind direction for optimal energy capture. This rotational capability introduces a design challenge: how to ensure efficient and safe access for maintenance personnel transitioning from the ladder or lift inside the tower to the internal walkway within the nacelle. This is typically solved by attaching a short section of ladder to the underside of the nacelle’s access hub. This rotating ladder moves with the nacelle, providing a reliable and consistent access point regardless of its orientation. The rotating ladder is reached from a fixed platform located directly beneath it, which is accessible via either the stationary ladder or the lift.

Accessing Components within a Housing

So far, we’ve explored examples of equipment and structures that require thoughtful design for external access. However, accessibility is equally important when it comes to reaching small components housed in tight spaces where only a person’s hands can fit. Any housing that is too small for a person to fit should have some easy means for a workers hands to articulate well within the available space.

A good example of a small housing designed for easier hand articulation is an electrical circuit breaker panel. When the front cover is opened, the breaker switches are neatly arranged in vertical rows and recessed into the back of the enclosure. While the layout is primarily dictated by the functional requirements of the breakers, accessibility is also a key consideration. There is ample space around the perimeter of the breakers to prevent a person’s hand from rubbing against the edges of the opening. Additionally, the breakers are not recessed so deeply that it feels like reaching into a narrow, deep cavity—the depth is proportionate to the width, allowing for comfortable access. Made even easier are the circuit breaker panels used for inside buildings, as they usually don’t require a cover since they remain unexposed to outdoor elements.

When multiple differing components cannot fit easily within a housing together, they may require a process of installation, thus, requiring a procedure to accessing specific components within the internals of the assembly. A great example of this is the engine components for a car. The arrangement of an engine’s components is primarily determined by where each part functions best in relation to the components it directly interacts with. However, accessibility plays a crucial role as well—designers and engineers must balance the need for easy, frequent access to certain parts with the challenge of fitting everything within a compact engine bay. Components that require regular inspection or maintenance, such as the oil dipstick, oil filter, battery, air filter, and coolant reservoir, are typically positioned toward the front and kept unobstructed. Placing these items beneath other components would make routine checks and top-ups unnecessarily difficult. As the front-first items are placed for easy handling, other accessing techniques are used for internal components that are harder to reach. Some vehicles use a modular engine layout, where components like coils, plugs, and injectors are easy to remove without needing to dismantle surrounding parts. And where parts cannot be accessed easily through the hood can be accessed from underneath the car after being jacked up higher from the ground.

While providing physical access to all engine components is important, some challenges are inevitable. A unique solution to this is accessing the engine without physically touching it—through electronic diagnostics. This is where the Engine Control Module (ECM) comes into play, which can be monitored via the On-Board Diagnostics (OBD-II) port. By connecting a diagnostic tool to this port, mechanics can identify potential issues before even opening the hood. In this sense, digital diagnostics offers a highly efficient form of engine accessibility. As technology continues to advance, these methods of accessing components and equipment are heavily being adopted, making accessibility for repairs sake much simpler.

Better Thought-out Access Brings Safer Conditions

Any well engineered facility that you come across will have someone behind the scenes ensuring that accessibility is not overlooked. Thoughtfully planning how a person will access a specific location not only enhances a design’s economics, efficiency, and aesthetics—but most importantly, it helps ensure user safety. With proper consideration, a designer can pinpoint the areas where human interaction is required, understand how that interaction should occur, and avoid unnecessary or overly complex design elements.

For individuals who must access these areas regularly—often alongside many other tasks—design efficiency becomes critical. Adding too many stairs or ladders, for example, can lead to unnecessary physical strain. Similarly, poorly planned layouts may force quick movement through tight spaces, increasing the risk of contact with hazards like hot surfaces. Simple adjustments, such as providing just a few extra inches of clearance, can significantly improve both safety and usability.

Conclusion

Like many areas of design, accessibility is a crucial element—one that, when overlooked, becomes noticeably absent. It plays a role in nearly everything you interact with. So next time you’re walking somewhere or reaching into an enclosure, take a moment to notice how accessibility has been considered to make your experience easier and safer. If you have enjoyed this article, feel free to comment and get future conversations started!