Engineering design encompasses a vast array of disciplines and practices, making it a remarkably diverse career path. Various branches, such as electrical, mechanical, and process engineering, offer different titles and opportunities for collaboration. However, another layer of versatility and expertise emerges with the distinctions between industrial design and commercial design, further enhancing the richness of the design landscape. While both industrial and commercial design are essential for meeting the economic needs of a community, they differ significantly in the services they offer and processes that each require.

Industrial design focuses on the creation and development of physical products, emphasizing functionality, usability, and aesthetic appeal. I can also be a field that focuses on the process of taking raw resources and processing them into usable resources. Designers in this field meticulously consider materials, ergonomics, and manufacturing processes to ensure that their products enhance the user’s quality of life. In contrast, commercial design is centered on crafting experiences that resonate with consumers and elevate brand identity. This discipline is crucial not only for the type of business that will operate in the space but also for factors influencing branding and marketing strategies, thereby enhancing the connection between customers and the products or services provided. By examining the ultimate goals of industrial and commercial design, we can better understand the key differences between these two disciplines and how they influence various factors. Let’s continue by further clarifying some of these distinctions.

Industrial Design

A key way to identify where industrial design occurs is by understanding its primary goal: developing usable products for consumers. For every product that someone would use, there is a process that has been utilized to create this product and bring it into the hands of consumers. This process is designed for maximizing functionality, manufacturability, and efficiency. Depending on the product manufactured, the more variety comes into play for the creation of the product, which involves the integration of complex systems to achieve the desired outcome, and highlights the need for skilled and specialized designers. Designers in industrial design typically operate on one of two fronts: they either conceptualize the final product and its appearance or work on refining the processes involved in manufacturing that product.

Designing the Product

Prior to the industrial production of a product, the prototype of it will undergo many iterations before settling on it’s final configuration, while accommodating many design factors to increase efficiency and lower costs. Many professionals of differing experiences will first undergo a phase of research and discovery to identify a specific problem that can be solved for that will then sprout the idea for a product. This idea of the product will then go through a complicated process of validating, testing, iterating and retesting (a process that has many complicated and fascinating stages which would be too much to cover in this article) until it reaches a functional prototype and enters a phase that begins to blend into an industrial design process. The beginning of the industrial design process will generally see the product undergo the phase of Design validation to ensure that the product can be manufactured efficiently. Design validation confirms that the product meets all specified requirements. Key activities during this phase include engineering validation, where engineers ensure the design is manufacturable. This is followed by compliance testing to verify safety and environmental standards. Materials are then selected and tested to ensure they perform under real-world conditions. Throughout the process, iterative improvements are made to fine-tune the design. These stages are critical to the industrial process, as the decisions made here will determine the machinery and equipment needed to shape the materials into the final product form.

Designing the Process

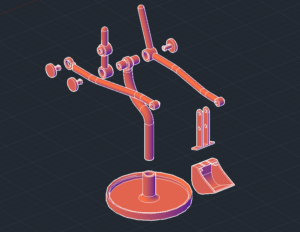

The final shape and form of a product will significantly influence the machines and systems used to mold or convert the starting materials into the desired outcome. For example, if a product was required to include a part that comprised of a flat plate bent at 90 degrees, then what would be the most efficient way to manufacture that piece? Would it be better to start out with a flat piece and then direct it to a machine that will bend it into 90 degrees, or would it be better to cast the material into a mold already set at 90 degrees? One may seem more obvious over the other, but it will depend on what is more efficient and what method works best for the given materials, along with many other factors involved. Many of these kinds of questions are addressed at the Pre-production and Manufacturing Preparation phase. The objective of this phase is to finalize all details for mass production and ensure the design can be scaled efficiently. Key activities during this phase involve the tooling and production planning, which is the designing of molds, dies, and other manufacturing tools, and requires in depth review by designers to plan for effective production. Supply chain coordination follows after, which involves establishing the suppliers and manufacturers for sourcing materials and components. During this process, CAD drawings and models will be developed by designers and engineers to lay out the equipment and any other facilities required to take the raw resource and convert it into a usable product. These other facilities within a products development process can include examples such as buildings, equipment structures, roads between plants, and storage centers. When everything is constructed and in its proper places, the site will undergo pilot runs and run small batches or small quantities to test the production process, quality control, and safety of the assembly line. After any design issues have been met and addressed, then large scale production begins.

Commercial Design

The primary goal of most facilities in commercial design is to create products, services, or experiences that enhance market appeal and drive sales. This includes designing spaces, structures, and environments intended to support the commercial or public objectives of businesses and organizations. Making the product or place of business attractive, engaging and functional for the target consumer is essential, which has an emphasis on fine tuning the aesthetic appeal and brand identity to induce a positive consumer behavior. Since aesthetics play a crucial role in commercial design, they are prioritized in the creation of a space. A visually appealing design not only makes a strong first impression but also fosters a positive ongoing experience, encouraging customers to return and engage with the product and eventually, turn a profit.

Understanding By Comparison

To garner a further understanding of commercial design, lets compare it with industrial design. Industrial design does not place as much focus on aesthetics, but more on productivity. The ‘aesthetics’ that comes into play within industrial design falls more under the guise of apparent practicality. For example, the internal structures of a coal processing plant does not need to consider things like color moods or product branding, rather the ‘aesthetics’ aligns with how trusting the structure looks to safely fulfill the role of housing all running equipment, storage, and other facilities that comes with a coal processing plant. Within the commercial design sector, a common example of a building you can find would be a typical bank. Before construction, the building’s design is carefully coded to ensure safety for customers. However, equal attention is given to aligning both the exterior and interior with specific branding strategies. This includes using colors that evoke particular moods and creating an environment that encourages customers to engage in their financial interests at the location.

There are times when areas of industrial design interact with commercial design, and also time where the two have some areas of overlap. A space that would be marketing and selling a particular product most likely had that product developed under an industrial design process. In areas of overlap, it would seem apparent that the steps taken to begin a concept and take it all the way to completion would be the same, or very similar, but it is important to realize that each of these steps requires different knowledge, skills, and expectations to appropriately complete each one under its respective sector. For instance, a structural designer with extensive experience in the industrial design sector may struggle to adapt to the commercial design industry. Each sector has distinct expectations for what constitutes an effective design, and what’s crucial in one may be irrelevant—or even inappropriate—in the other. For example, focusing on aesthetic architectural concept drawings might be valued in commercial design but could be seen as an inefficient use of budgeted hours in industrial design. Some other factors affected by differences such as this can be project scheduling, design codes, and emphasis on areas within the design process. To gain a clearer understanding of the process involved in a commercial design project, let’s briefly go over some of the key steps that are essential to completing a commercial design.

the Process

As noted earlier under the ‘industrial design’ section, a significant focus is placed on creating processes that efficiently produce a product. In contrast, commercial design doesn’t require the same level of attention to developing a unique production system for a specific useable product. Instead, the primary goal is to design a space that facilitates the delivery of services. The process in commercial design typically follows a more standardized, step-by-step approach, taking the project from initial concept to a completed space that serves as a place of business.

Project planning and Brief Development

The commercial design process begins with a client consultation to understand their goals, budget, and the intended use of the space (e.g., office, retail, or mixed-use). Following this, a site analysis is conducted to assess factors such as location, zoning, and infrastructure. A detailed design brief is then developed, outlining the functional requirements, aesthetic preferences, budget, timeline, and sustainability goals, which will guide the rest of the design process.

Conceptual and Schematic Design

Based on the client’s brief, architects and designers create initial concepts to explore the building’s layout, flow, and functionality. Space planning is focused on optimizing the use of space. Preliminary sketches and diagrams help visualize these early ideas, which are presented to the client for feedback. Once a direction is approved, more refined schematic plans are developed, including floor plans, elevations, and material selections. Early integration of building systems, such as HVAC, plumbing, and electrical, also begins at this stage.

Design Development

In this phase, the design is further refined with more technical details. Detailed architectural drawings are created, specifying materials, finishes, and internal layouts. Collaboration with structural engineers and other specialists ensures the design is feasible and safe, leading to any necessary adjustments. 3D visualizations or renderings are also created to provide a realistic view of the space, helping clients better understand the final result.

Construction Documentation and Permitting

The final set of construction documents is prepared, including floor plans, elevations, and material specifications. These documents are essential for obtaining the necessary building permits, which ensure compliance with local codes and regulations. After permits are secured, contractors are invited to bid on the project, and a construction team is selected.

Construction Phase

Once construction begins, designers and architects remain involved to oversee that the work aligns with the approved plans. Regular site inspections and meetings with the contractor help ensure quality control and address any issues. Throughout this phase, specialists, such as landscape architects and interior designers, collaborate to ensure every aspect of the building is executed as envisioned.

Interior Design and Finishing

Interior designers focus on the final layout and design of the building’s interiors. This includes selecting furniture, lighting, color schemes, and finishes that align with the space’s function. Signage and branding are also incorporated to enhance the user experience and guide visitors. Sustainability features, such as energy-efficient systems or eco-friendly materials, are increasingly important in modern commercial design.

Final Inspections and Handover

Before the building is handed over to the client, it undergoes final inspections to ensure compliance with safety, health, and regulatory codes. This includes checking fire safety, accessibility, electrical, and plumbing systems. A final walkthrough with the client is conducted to ensure the space meets expectations, and any last-minute adjustments are addressed. Once everything is complete and passes inspections, the building is ready for occupancy and officially opens for business.

Post-Occupancy Evaluation

After the building is occupied, designers may gather feedback on its functionality. This can lead to future adjustments or renovations, especially for large commercial spaces. Additionally, regular maintenance and upgrades are essential to keep the building functional and up-to-date with evolving needs and technologies.

In Conclusion

In conclusion, engineering design is a dynamic and multifaceted field, offering a wide range of career opportunities across various disciplines. The distinction between industrial and commercial design adds yet another layer of depth, with each focusing on unique processes and services. While both play crucial roles in addressing the economic needs of society, they do so in fundamentally different ways, highlighting the versatility and complexity of the design landscape. Whether you’re drawn to the technical side or the creative aspects, the field of engineering design provides endless opportunities for innovation and impact. There is still much more to explore outside of what was discussed in this article, so comment if you would like to see coverage on any topics in more detail!