For designers and engineers, being introduced to 3D printing evokes the same sense of wonder as a child visiting a theme park. These clever machines empower anyone to create almost any physical shape they can imagine. But every printed design invites an essential question about its practical use. Just because you can 3D print a shape that resembles a full-sized car tire doesn’t mean it will perform like the real thing. There are several factors in this example that rule it out completely, such as material properties, strength, and capacity to hold air pressure, to name a few.

While many 3D print ideas can be quickly ruled out as impractical, some challenge us to think harder before determining the difference. This isn’t to say that the fun and harmless designs don’t always have their place, though. Think of this as an engineering and design exercise. Once you grasp how 3D printing works, you can critically evaluate your ideas before putting them on paper. Then you can rule out impractical design ideas. Before breaking down each idea, here’s a quick explanation of how 3D-printed objects are made.

3D printing – Basics

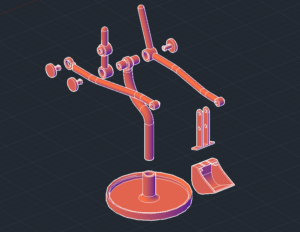

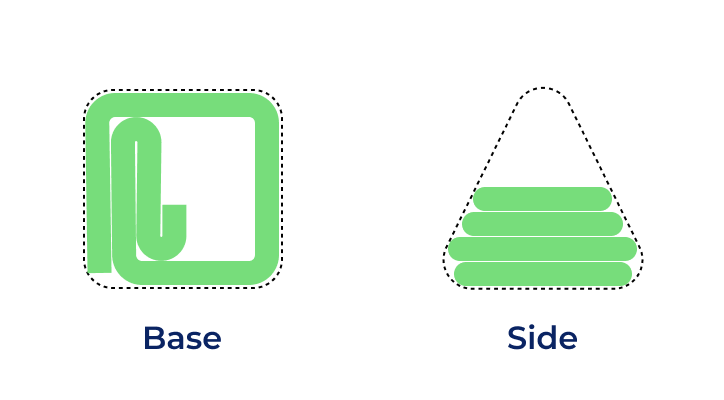

Most 3D printers build objects layer by layer. Many achieve this by melting plastic filament through a heated extruder and depositing each new layer directly on top of the previous one. Printers that operate this way are called FDM printers.

The printer follows a digital file that contains step-by-step instructions for moving along the X and Y axes. As it moves the extruder according to these instructions, it extrudes melted filament, slowly building the object one layer at a time.

This method of fabrication lets you make just about anything you can imagine. You can even build shapes inside other shapes without having to create separate pieces to fit around them. However, there comes a flaw to the resulting object, that being of a structural nature.

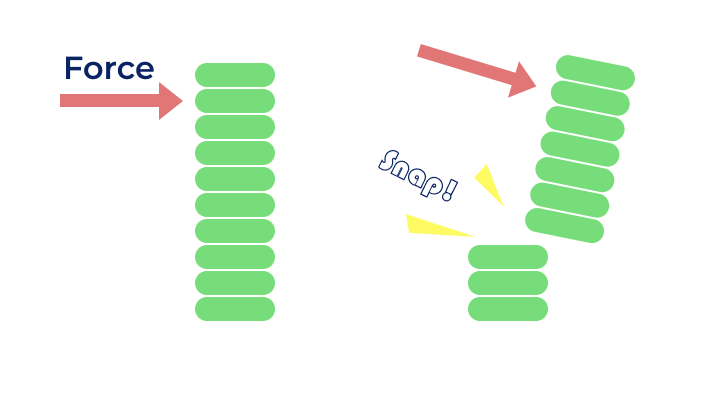

Each new layer melts and fuses directly onto the layer below it. The finished object isn’t a single solid piece; it consists of hundreds of plastic strands bonded together. This presents an inherit weakness in how it reacts to external forces. This including how and where these forces can be applied without the object breaking. Strong forces applied parallel to the print layer easily breaks an object along the seams where the layers bond.

Another issue that arises from this process is the possibility of external imperfections becoming embedded in the finished object. As each layer is printed, dust or other airborne particles can settle on the surface before the next layer is deposited. This adds to the issues of structural strength, and presents other negative points that we will later discuss in detail. If you want to continue learning more about 3D printing in detail, you can find more information here.

Avoid 3D printing the following

These fundamental properties of 3D-printed objects play a significant role in determining how effective they are in their final form. The following examples highlight situations in which 3D-printed objects do not produce an efficient end product.

1. Push-up handles and other Workout Equipment

The shape for push-up handles offer a solid workout, but due to it’s shape, it is necessary to fabricate them form a material that can take a heavy load. Injection molded plastics, steel, aluminum, and wood being common materials for their capacity to support these expected loads. Forming the shape of these by means of 3D printing will subject push-up handles to many points of failure. While in use, the body builder places their hand, i.e. a point of load, at the center of the handles, causing a strain at the support locations. Stronger materials can resist this strain, but an object built from several individual layers now introduces several locations where that strain can cause a fail point.

Failure of a push-up handle mid workout is bad enough, but due to the layering of 3D printed objects, the locations of failure have a potential of being sporadic. Rather than one clean break line, the object can fracture into smaller fraying pieces, some of those potentially being sharp and can easily lodge into your skin.

Needless to say, Failing work-out equipment is a first rate introduction to severe bodily injury. The materials used to build push-up handles and other calisthenics equipment directly determine their safety and performance. Spending a little more on properly constructed equipment is far better than paying the price with your body.

2. Anything you Stand on

Closely related to the previous topic, this point deserves its own section. Equipment that people stand on—such as ladders, stools, or walking stilts—should never be 3D-printed. Load-bearing equipment must use strong materials that can withstand off-center loads. These items become especially dangerous because people may stay on them for extended periods. For example, a worker can remain on a ladder for a long time, increasing the potential of an accident happening.

In addition to length of time, height introduces another dangerous factor. These are bad enough, but a failing 3D printed ladder or stool simply enhances the possibility of this happening. Simply put, by your ladders and stools form the hardware store.

3. Tools – Anything put under High Strain

Wrenches, pliers, and other hand tools are designed to handle stress and perform efficiently in their specific tasks. However, these tools rely on the strength of their materials to withstand the forces they will experience during use. Tools made with a 3D printer may look impressive, but plastic filament flails under the same conditions metal tools are place in. As soon as plastic tools experience similar torques or moments (a force applied at a distance form a fixed point), it will easy fail. It could skip teeth, easily wear down or snap into pieces all together.

The surfaces of operating machinery often reach temperatures higher than the filament can tolerate. Many of these tools also come into contact with heavily spilled oil. That oil can seep into the seams between layers, weakening the plastic over prolonged exposure. The oil resistance of the 3D printed tool depends on the type of filament, but this shouldn’t be a deciding factor to making the tool by 3D printing or not. Unless you want to use it as a cool looking desk toy, you’re better off buying proper tools designed for the job.

4. Object touching Foods or Drinks

As a 3D printer builds an object, it melts the filament and fuses each layer. As the plastic melts and cools, it develops microscopic imperfections. Small particles and fragile residue can break off the surface, leaving traces on anything the object touches. Additionally, as the surface breaks away, anything that had been trapped between the layers while printing is now released. This includes dust, airborne imperfections and possibly bacteria.

Now, ask yourself this, does this sound appetizing? If it doesn’t, then you should avoid using 3D printed bowls, whisks, spoons and anything that touches food. Ingesting these micro plastics over long periods of time will result in negative health side effects. For your safety, stick to buying your kitchen tools from the proper sources.

5. Anything exposed to High Temperatures

The 3D printing process heats and melts plastic filament to form each piece, so exposure to similar heat will cause it to melt and deform. It’s obvious that these plastic based objects should be distanced from a kitchen stove, but there are applications that are less obvious. A blow dryer adapter, for example, is a melted mistake waiting to drip hot plastic onto your scalp. And that dashboard toy that gives your car personality sits in extreme heat while your car bakes in the summer sun.

3D printed parts losing their shape due to heat is the least concerning factor. Touching melted plastic will easily leave someone with a burn, and the type of filament raises issues as well. When such filaments like ABS (Acrylonitrile Butadiene Styrene) or ASA (Acrylonitrile Styrene Acrylate) melt, they can release harmful fumes into the air. This is especially concerning if it melted in an enclosed space with little or no ventilation. Heat exposed objects should be made from heat resistant materials, and 3D printing should be left out of it.

3D printing makes it exciting to watch ideas come to life, but designers must carefully evaluate every concept—including their own—for practicality and safety. Adopting this mindset strengthens design skills and helps focus efforts on objects and pieces that truly suit the strengths of 3D printing.